Sonoperoxone® Blackwater System Users experience these money saving advantages over conventional green sand systems with:

- Reduced new bond & solid waste disposal expenses due to 15% to > 40% reduction in new bond purchases. In some cases, new sand additions have also been significantly reduced.

- Reductions in sand related scrap rates from 10% to 50%.

- Improved activation and re-activation of clay resulting in higher compressive and shear strength per unit of clay, without creating shakeout problems.

- Increased mold density and stiffness that reduces mold wall movement, shrink defects and casting swell. In a well documented case, this reduction in mold wall movement reduced casting swell related shrink defects up to 50% and reduced electric melt energy on castings prone to swelling by up to 7%.

- Improved sand system control resulting in a more predictable and understandable sand system.

- Improved indoor air quality that allows reduced make up air dilution. This means significantly lower make-up air heating costs are possible in cold climate winters

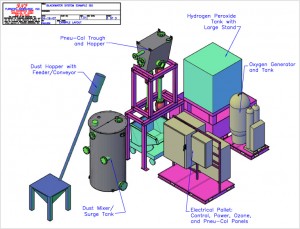

Sonoperoxone® Blackwater System Diagrams

These diagrams illustrate possible arrangements for the basic components in a Sonoperoxone® blackwater system. The actual configuration is tailored to fit the unique needs of each customer.

Typically, the system can be installed in an area 10 feet wide by 20 feet long. The location of the Sonoperoxone® system is determined by considering the logistics of the generation point for the dust to be recycled and the use point for the blackwater.

While the science involved in the system is very complex, the process flow is fairly straightforward. Dust is added to the water treated with ozone and hydrogen peroxide in the dust mixer/surge tank and the mixture is subjected to high intensity acoustic energy. The resultant slurry, referred to as blackwater,

is pumped to various inputs in the foundry that formerly used city water. The returning blackwater is put through a settling process, the Pneu-Col® portion of the system, to remove a portion of the fines.

Usually nearly all of the discharge from the Pneu-Col® is fine silica sand. The remaining blackwater returns to the system and the cycle begins again. City water is added to the dust mixer/surge tank to make up for the blackwater added to the foundry processes.